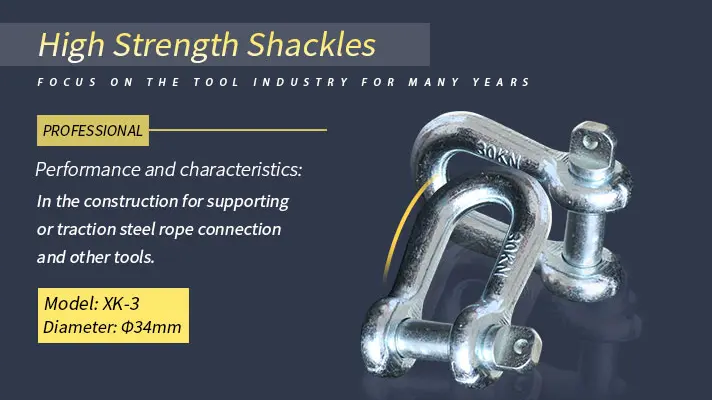

High strength shackles are a type of fastener used in many applications where a secure and reliable connection is needed. These shackles are made from high strength materials such as steel, stainless steel, and alloys that are designed to withstand heavy loads and resist corrosion. They are often used in lifting, towing, and mooring operations, and in machinery and construction applications.

One of the main uses of high strength shackles is to secure two or more components together. The shackle is usually composed of a pin and a body, with the pin passing through the body and secured with a nut. Shackles are available in a variety of sizes and shapes, depending on the application.

The high strength of these shackles makes them ideal for use when other fastening components may fail due to the force applied. They can also be used to join two or more pieces of material of different sizes or shapes. They are also commonly used to secure crane booms, mooring lines, and other heavy-duty applications.

High strength shackles are also often used in the automotive industry, where they are used to secure components such as fuel tanks, radiators, exhaust systems, and transmission assemblies. They can also be used to secure winches and other lifting equipment, as well as to secure mooring lines.

High strength shackles are a versatile fastening component that is used in a variety of applications. They are strong, reliable, and highly resistant to corrosion and wear, making them ideal for use in many different industries.

What Is High Strength Shackle?

High strength shackles are a type of fastener used in many applications where a secure and reliable connection is needed. They are usually composed of a pin and a body, with the pin passing through the body and secured with a nut. High strength shackles are typically made from high strength materials such as steel, stainless steel, and alloys that are designed to withstand heavy loads and resist corrosion. They are available in a variety of sizes and shapes, depending on the application.

High strength shackles are used for a variety of applications, such as securing items to walls or other structures, fastening cables and chains, and connecting co

mponents in industrial machinery. These shackles are made from high-strength materials such as stainless steel and are designed to withstand extreme temperatures, pressures, and other environmental conditions. They are most commonly used in the aerospace, automotive, and construction industries.

High strength shackles are designed to provide superior strength and durability when compared to standard shackles. The shackles are made with a variety of designs and sizes to meet the needs of different applications. Some of the most common designs include screw pin shackles, bow shackles, and dee shackles. All of these types of shackles are designed to provide high levels of strength and security.

High strength shackles are also used in marine applications, such as mooring lines, anchor lines, and towing lines. These shackles are designed to provide superior strength and corrosion resistance in saltwater environments. Additionally, stainless steel shackles are often used to secure items to buoys, boats, and docks, as well as to secure anchors and other heavy objects to the seabed.

What Are the Uses of High Strength Shackle?

High strength shackles are used in many applications, including lifting, towing, and mooring operations, and in machinery and construction applications. They are also used to secure components in the automotive industry, such as fuel tanks, radiators, exhaust systems, and transmission assemblies. High strength shackles are highly resistant to corrosion and wear, making them ideal for use in many different industries.

Types of High Strength Shackle?

There are a variety of types of high strength shackles available, including Clevis, Bow, Dee, and Shackle Links. Clevis shackles are the most commonly used type, and they are typically composed of a pin, body, and nut. Bow shackles have an open loop design, and are commonly used for attaching components such as cables and chains. Dee shackles have a closed loop design and are used to attach components such as lifting slings. Shackle Links are a type of shackle that is used to connect components together.

Benefits of using a High Strength Shackle

High strength shackles are a versatile fastening component that is used in a variety of applications. They are strong, reliable, and highly resistant to corrosion and wear, making them ideal for use in many different industries. In addition, they are usually easier to install than other fastening components, which can save time and money.

Pros and Cons of using a High Strength Shackle

Pros:

• High strength shackles are strong, reliable, and highly resistant to corrosion and wear.

• They are available in a variety of sizes and shapes, depending on the application.

• They are usually easier to install than other fastening components, which can save time and money.

Cons:

• High strength shackles can be expensive.

• They may require specialized tools for installation.

• They may not be suitable for use in extreme temperature conditions.

High Strength Shackle work?

High strength shackles use a pin and a body to secure two or more components together. The pin passes through the body and is secured with a nut. The high strength of these shackles makes them ideal for use when other fastening components may fail due to the force applied. They can also be used to join two or more pieces of material of different sizes or shapes.

Conclusion

High strength shackles are a versatile fastening component that is used in a variety of applications. They are strong, reliable, and highly resistant to corrosion and wear, making them ideal for use in many different industries. They are usually easier to install than other fastening components, which can save time and money. However, they can be expensive and may require specialized tools for installation.