Introduction:

The closed chock is a common ship device installed on the ship to guide the movement of the ropes. In the ISO 13729-2012 standard, there are two types of closed chocks: A type and B type. Type A is installed on the deck and type B is installed on the bulwark.

The marine chock is an important mooring equipment. There’re different types of mooring chocks with different standards including ISO, JIS, DIN, NS. SWL will be from 8KN to 3000KN according to your requirements. In the process of mooring ship, it bears huge loads. Usually, the ship bollards and mooring chock are for the whole ship mooring use. The general bow and stern of ship block the bollard fairlead, quantity large. Of intermediate section above without or bollards, fairlead rarely. Fairlead is oblique chock more insurance, because it is closed, the cable will not jump out. The triangle chocks are widely used for small boats and different vessels, such as container vessels, tankers, bulk carriers, tug, dry cargo vessels, etc.

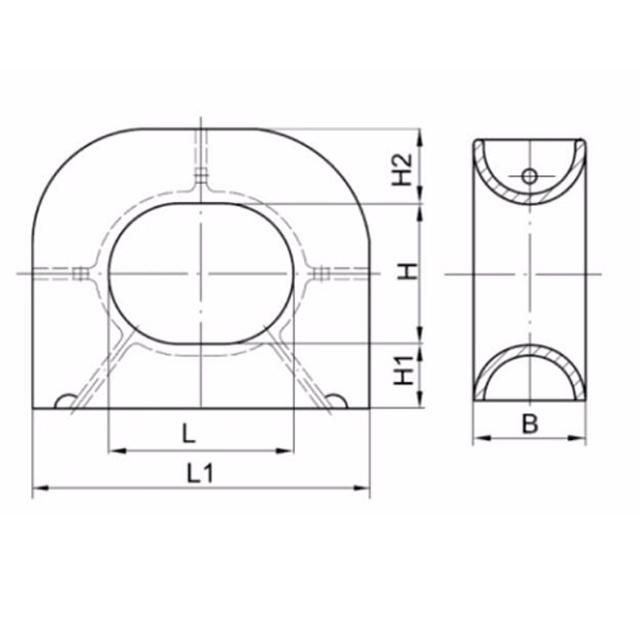

Marine mooring chock has two types: deck mounted chock & bulwark mounted chock. The material is casting steel ZG230-450 normally. IACS approved quality to withstand all conditions. Certificated by BV, ABS, LRS, DNVGL, RS, IRS, CCS, KR, NK, etc. We could also provide you with a customized design with CAD drawings.