Introduction:

The mooring chock is made according to the ISO 13713 standard and is a type of ship’s mooring and towing fitting installed on the shipside to lead the mooring and towing rope from the ship’s inboard to outboard. The mooring chocks are normally adopted for ships that use nylon or other synthetic ropes rather than wire ropes considering the small bending ratio (for wire rope see ISO13729 closed chocks). The tensile strength of the rope is reduced depending on the bend radius through the chock in accordance with the rope manufacture’s guidelines. All surfaces, including welding, shall be free from any visible flaws or imperfections and in contact with the ropes, shall be free from surface roughness or irregularities likely to cause damage to the ropes by abrasion. The chock should be coated externally with an anti-corrosion protective finish.

The ISO13713 chock has two types depend on its installation including deck mounted one and bulwark mounted one.

The marine chock is an important mooring equipment. There’re different types of mooring chocks with different standards including ISO, JIS, DIN, NS. SWL will be from 8KN to 3000KN according to your requirements. In the process of mooring ship, it bears huge loads. Usually, the ship bollards and mooring chock are for the whole ship mooring use. The general bow and stern of ship block the bollard fairlead, quantity large. Of intermediate section above without or bollards, fairlead rarely. Fairlead is oblique chock more insurance, because it is closed, the cable will not jump out. The triangle chocks are widely used for small boats and different vessels, such as container vessels, tankers, bulk carriers, tug, dry cargo vessels, etc.

Marine mooring chock has two types: deck mounted chock & bulwark mounted chock. The material is casting steel ZG230-450 normally. IACS approved quality to withstand all conditions. Certificated by BV, ABS, LRS, DNVGL, RS, IRS, CCS, KR, NK, etc. We could also provide you with a customized design with CAD drawings.

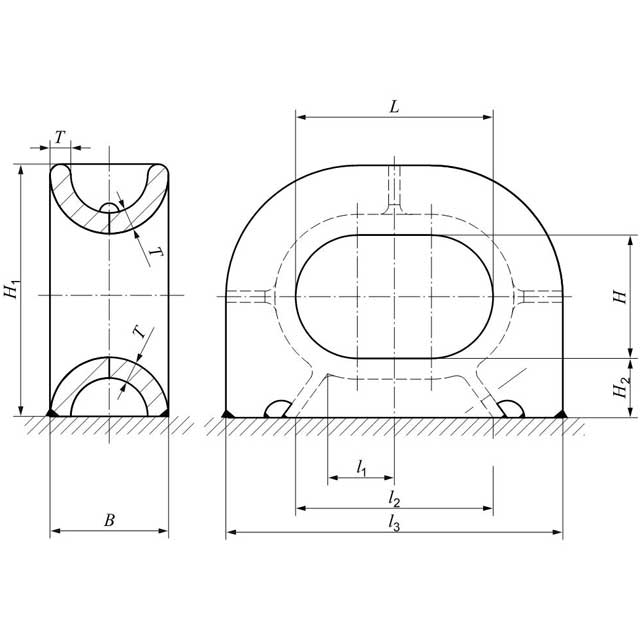

Drawing of ISO13713 Deck Mounted Mooring Chock (Type A)

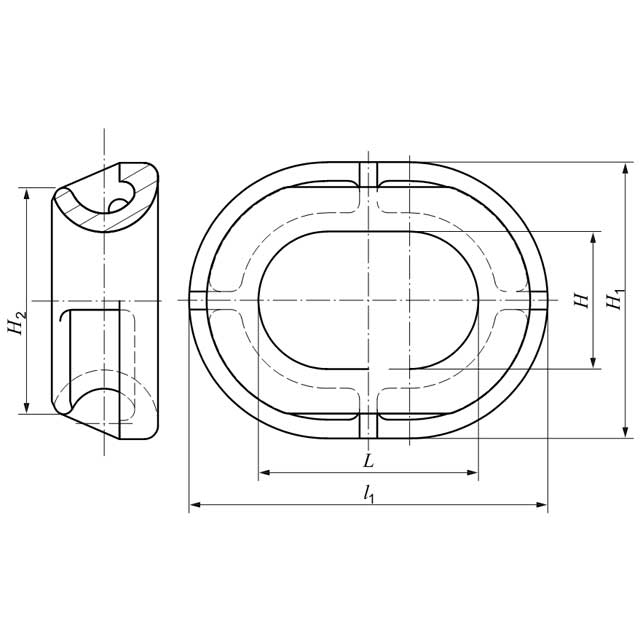

Drawing of ISO13713 Deck Mounted Mooring Chock (Type B)