A forged shackle is a type of hardware item used in a variety of applications, including rigging and load securement. It is made by shaping metal into a specific shape and size using a forging process. Forging is a manufacturing process that involves the use of pressure to shape metal into a desired shape. The forging process can provide superior strength and durability, and is often used to create components that will be exposed to extreme conditions.

A forged super shackle is a type of shackle that is made from a higher grade of metal, such as high-strength steel alloys. This type of shackle is designed to be extremely strong and durable, and can often be used in applications that require high levels of load bearing and securement. They are often used in applications such as shipbuilding, construction, and the transportation of heavy loads.

Forged super shackles are available in a variety of sizes, shapes, and designs. They can be used in a variety of applications, and are particularly well-suited for applications that require a strong, durable connection with minimal weight. They are often used in applications where strength and durability are of the utmost importance.

Overall, a forged super shackle is a type of hardware item used in a variety of applications that can provide superior strength and durability. They are often used in applications where strength and durability are of the utmost importance, and can be used to securely connect and bear heavy loads.

What is a Forged super shackle?

A forged super shackle is a type of shackle that is made from a higher grade of the metal, such as high-strength steel alloys. This type of shackle is designed to be extremely strong and durable, and can often be used in applications that require high levels of load bearing and securement. They are often used in applications such as shipbuilding, construction, and the transportation of heavy loads.

Forged super shackles are available in a variety of sizes, shapes, and designs. They can be used in a variety of applications, and are particularly well-suited for applications that require a strong, durable connection with minimal weight. They are often used in applications where strength and durability are of the utmost importance.

Overall, forged super shackles provide superior strength and durability, and are often used in applications that require a strong, secure connection and the ability to bear heavy loads.

The forged super shackle is one of the most reliable and secure pieces of hardware available, and is often used in applications where strength and durability are of the utmost importance.

The History of Forged Super Shackles:

Forged super shackles have a long history in the fields of rigging and load securement. The use of forged metal for the production of shackles dates back to ancient times, when the forging process was used to create strong, durable components for use in war and other applications.

The use of forged super shackles was popularized in the 18th century when the industrial revolution made it easier to produce high-strength steel alloys. This made it possible to create shackles that were stronger and more durable than ever before.

Today, forged super shackles are still widely used in the fields of rigging and load securement. They are used in a variety of applications, and provide superior strength and durability. They are often used in applications where strength and durability are of the utmost importance.

What are forged super shackle types?

Forged super shackles come in a variety of sizes, shapes, and designs. The most common types of forged super shackles are:

• Anchor shackles: Anchor shackles are typically used for connecting cables, ropes, and chains. They are typically made from high-strength steel alloys and feature a large loop on the end, which makes them ideal for connecting and bearing heavy loads.

• U-shackles: U-shackles are typically used for connecting cables, ropes, and chains. They feature a U-shaped loop on the end, which makes them ideal for connecting and bearing heavy loads.

• Bow shackles: Bow shackles are typically used for connecting cables, ropes, and chains. They feature a bow-shaped loop on the end, which makes them ideal for connecting and bearing heavy loads.

• Dee shackles: Dee shackles are typically used for connecting cables, ropes, and chains. They feature a D-shaped loop on the end, which makes them ideal for connecting and bearing heavy loads.

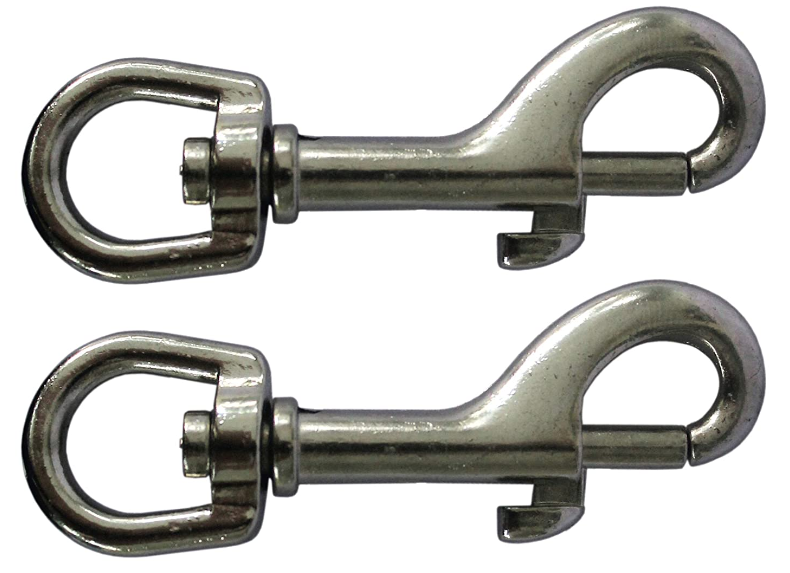

• Swivel shackles: Swivel shackles are typically used for connecting cables, ropes, and chains. They feature a swiveling loop on the end, which makes them ideal for connecting and bearing heavy loads.

Overall, forged super shackles are available in a variety of sizes, shapes, and designs. They can be used in a variety of applications, and are particularly well-suited for applications that require a strong, durable connection with minimal weight.

What is a forged super shackle used for?

Forged super shackles are used in a variety of applications, including rigging and securement. They are often used in applications where strength and durability are of the utmost importance, and can be used to securely connect and bear heavy loads.

Forged super shackles are commonly used in shipbuilding, construction, and the transportation of heavy loads. They can also be used in industrial and agricultural applications, as well as in recreational activities such as camping and climbing.

Overall, forged super shackles are used in a variety of applications that require a strong, secure connection and the ability to bear heavy loads.

The benefits of forging a super shackle.

Forging is a manufacturing process that involves the use of pressure to shape metal into a desired shape. The forging process can provide superior strength and durability and is often used to create components that will be exposed to extreme conditions.

The benefits of forging a super shackle include:

• Increased Strength: Forged super shackles are made from high-strength steel alloys, which are designed to be extremely strong and durable. This increased strength makes them ideal for applications that require load bearing and securement.

• Reduced Weight: Forging is a process that involves shaping metal into a specific shape and size. This can help reduce the overall weight of the shackle, which can be beneficial in applications where weight is a factor.

• Improved Durability: The forging process can provide superior strength and durability, which can help ensure that the shackle will be able to withstand extreme conditions.

Overall, the forging process can provide superior strength and durability, and is often used to create components that will be exposed to extreme conditions. This makes forged super shackles an ideal choice for applications that require load bearing and securement.

Conclusion: The benefits of forging a super shackle are vast and include increased strength, durability, and accuracy.

Forged super shackles are one of the most reliable and secure pieces of hardware available, and are often used in applications where strength and durability are of the utmost importance. They are available in a variety of sizes, shapes, and designs, and can be used in a variety of applications, including shipbuilding, construction, and the transportation of heavy loads.

Overall, forged super shackles provide superior strength and durability, and are often used in applications that require a strong, secure connection and the ability to bear heavy loads.